Products

C Purlin Steel Roll Forming Machine manufacturer

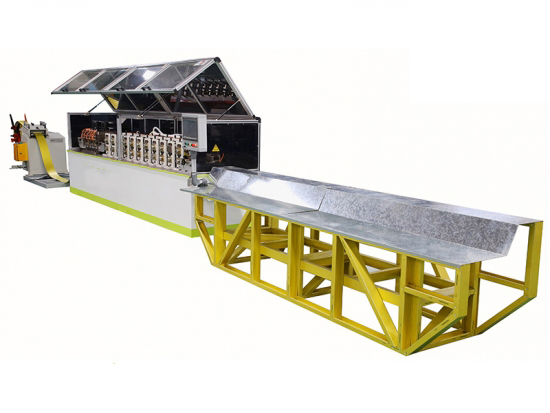

Automatic C Purlin Roll Forming Machine

Automatically working process and change the profile width to be different size. Easy operation with PLC.

Automatic C Purlin Roll Forming Machine is an equipment that produces C shaped steel channels continuously and it can continuously automatically uncoiling, leveling, punching, roll forming, post cutting and output.

Machine can change C profile to be different sizes automatically. Just push the button and the rollers will automatically adjust the required sizes without being adjusted manually.

The machine can be customized based on the customer's specific technical requirements.

Automatic C Purlin Roll Forming Machine

Automatically working process and change the profile width to be different size. Easy operation with PLC.

Automatic C Purlin Roll Forming Machine is an equipment that produces C shaped steel channels continuously and it can continuously automatically uncoiling, leveling, punching, roll forming, post cutting and output.

Machine can change C profile to be different sizes automatically. Just push the button and the rollers will automatically adjust the required sizes without being adjusted manually.

The machine can be customized based on the customer's specific technical requirements.

Automatic CZ Interchange Purlin Roll forming Machine

Can do both CZ profiles in one machine, CZ profile switch automatically, profile dimensions change automatically.

Automatic CZ Interchange Purlin Roll forming Machine can produce both C channel and Z change profiles in one machine, and the machine can change the profile and specifications automatically, while without replace the rollers if want to do different purlins with different specifications. It can automatically uncoiling, leveling, punching, roll forming, cutting and output.

Special sizes of purlin can be designed in our company. The machine can be customized based on the customer's specific technical requirements.

Automatic CZ Interchange Purlin Roll forming Machine

Can do both CZ profiles in one machine, CZ profile switch automatically, profile dimensions change automatically.

Automatic CZ Interchange Purlin Roll forming Machine can produce both C channel and Z change profiles in one machine, and the machine can change the profile and specifications automatically, while without replace the rollers if want to do different purlins with different specifications. It can automatically uncoiling, leveling, punching, roll forming, cutting and output.

Special sizes of purlin can be designed in our company. The machine can be customized based on the customer's specific technical requirements.

C Channel Roll Forming Machine

Continuous working process, high efficiency flying cutting, change roll forming cassettes to switch profiles.

Automatic C Channel Roll Forming Machine is an equipment that produces C shaped steel channels continuously and it can continuously automatically uncoiling, straightening,roll forming, post cutting and output.

This machine has two roll forming units. And each unit adopts cassette type. When user need to change different sizes, it only needs to be performed by removing one cassette and installing another without additional adjustments.

The machine can be customized based on the customer's specific technical requirements.

C Channel Roll Forming Machine

Continuous working process, high efficiency flying cutting, change roll forming cassettes to switch profiles.

Automatic C Channel Roll Forming Machine is an equipment that produces C shaped steel channels continuously and it can continuously automatically uncoiling, straightening,roll forming, post cutting and output.

This machine has two roll forming units. And each unit adopts cassette type. When user need to change different sizes, it only needs to be performed by removing one cassette and installing another without additional adjustments.

The machine can be customized based on the customer's specific technical requirements.

Highspeed CZ Purlin Roll forming Machine

Advanced machine layout to increase the working speed. Automatic switch CZ profile and change dimensions.

Highspeed CZ Interchange Purlin Roll forming Machine is an equipment that produces C/Z shaped steel channels continuously out of galvanized or cold rolled steel strips from feeding, punching for holes, roll forming , cutting and output.

We design the whole line separated to be decoiling, leveling, loop, servo feeding&punching, roll forming unit, output. The layout arrangement is more advanced than the traditional type. Because there are loops in the line to synchronize the speed for each individual part. Thus, we can achieve higher running speed.

Highspeed CZ Interchange Purlin Roll forming Machine can do both C and Z shape purlin in one machine with different sizes, automatic adjustment. Special sizes of purlin can be designed in our company.

Highspeed CZ Purlin Roll forming Machine

Advanced machine layout to increase the working speed. Automatic switch CZ profile and change dimensions.

Highspeed CZ Interchange Purlin Roll forming Machine is an equipment that produces C/Z shaped steel channels continuously out of galvanized or cold rolled steel strips from feeding, punching for holes, roll forming , cutting and output.

We design the whole line separated to be decoiling, leveling, loop, servo feeding&punching, roll forming unit, output. The layout arrangement is more advanced than the traditional type. Because there are loops in the line to synchronize the speed for each individual part. Thus, we can achieve higher running speed.

Highspeed CZ Interchange Purlin Roll forming Machine can do both C and Z shape purlin in one machine with different sizes, automatic adjustment. Special sizes of purlin can be designed in our company.

Cassette Type Sigma Purlin Roll Forming Machine

Advanced layout to increase working efficiency. Auto change profile width. Cassette structure for switch profiles.

Cassette Type Sigma Purlin Roll Forming Machine is especially used for producing the Sigma profile, which can be column or beam with different combination. The whole line adopts PLC controlling system and AV inverter speed adjustment, it can run full automatically.

We design the whole line separated to be decoiling, leveling, loop, servo feeding&punching, loop, roll forming unit, output. The layout arrangement is more advanced than the traditional type. Because there are loops in the line to synchronize the speed for each individual part. It adopts two cassettes to produce two profiles, i.e. Sigma profile and Z profile.

The machine can be customized based on the customer's specific technical requirements.

Cassette Type Sigma Purlin Roll Forming Machine

Advanced layout to increase working efficiency. Auto change profile width. Cassette structure for switch profiles.

Cassette Type Sigma Purlin Roll Forming Machine is especially used for producing the Sigma profile, which can be column or beam with different combination. The whole line adopts PLC controlling system and AV inverter speed adjustment, it can run full automatically.

We design the whole line separated to be decoiling, leveling, loop, servo feeding&punching, loop, roll forming unit, output. The layout arrangement is more advanced than the traditional type. Because there are loops in the line to synchronize the speed for each individual part. It adopts two cassettes to produce two profiles, i.e. Sigma profile and Z profile.

The machine can be customized based on the customer's specific technical requirements.

Light Steel Frame Roll Forming Machine

Smart electric operation system. Fully automatically machine working procedure. Standard light steel frame.

Fully Automatic Light Gauge Steel Frame Roll Forming Machine is mainly used in the production of light steel frame building. The machine is artistically made and transmits smoothly at a low noise. It is a kind of very welcomed modern building material with better anti-press and anti-bending performance, and is widely used in the building of garden like factories, civil-construction and mansions, etc. Its length is set according to customer’s requirements and transportation situation. Its color is selected from the color code of the steel factory.

The machine can be customized based on the customer's specific technical requirements.

Light Steel Frame Roll Forming Machine

Smart electric operation system. Fully automatically machine working procedure. Standard light steel frame.

Fully Automatic Light Gauge Steel Frame Roll Forming Machine is mainly used in the production of light steel frame building. The machine is artistically made and transmits smoothly at a low noise. It is a kind of very welcomed modern building material with better anti-press and anti-bending performance, and is widely used in the building of garden like factories, civil-construction and mansions, etc. Its length is set according to customer’s requirements and transportation situation. Its color is selected from the color code of the steel factory.

The machine can be customized based on the customer's specific technical requirements.

Steel Deck Roll Forming Machine

Automatic producing process. High speed and accurate punching system, cassette system for switch profiles.

Automatic Scaffold Walk Deck Roll Forming Machine is for producing the scaffolding board. It can uncoil, level, punch and continuously roll forming with automatic cutting to length. It is the essential equipment in the steel structure industry.

The machine can be customized based on the customer's specific technical requirements.

Steel Deck Roll Forming Machine

Automatic producing process. High speed and accurate punching system, cassette system for switch profiles.

Automatic Scaffold Walk Deck Roll Forming Machine is for producing the scaffolding board. It can uncoil, level, punch and continuously roll forming with automatic cutting to length. It is the essential equipment in the steel structure industry.

The machine can be customized based on the customer's specific technical requirements.

Automatic Z Purlin Roll Forming Machine

Automatically working process and change the profile width to be different size. Easy operation with PLC.

Automatic Z Purlin Roll Forming Machine is an equipment that produces Z shaped steel continuously and it can continuously automatically uncoiling, leveling, punching, roll forming, post cutting and output.

Machine can change Z profile to be different sizes automatically. Just push the button and the rollers will automatically adjust the required sizes without being adjusted manually.

The machine can be customized based on the customer's specific technical requirements.

Automatic Z Purlin Roll Forming Machine

Automatically working process and change the profile width to be different size. Easy operation with PLC.

Automatic Z Purlin Roll Forming Machine is an equipment that produces Z shaped steel continuously and it can continuously automatically uncoiling, leveling, punching, roll forming, post cutting and output.

Machine can change Z profile to be different sizes automatically. Just push the button and the rollers will automatically adjust the required sizes without being adjusted manually.

The machine can be customized based on the customer's specific technical requirements.

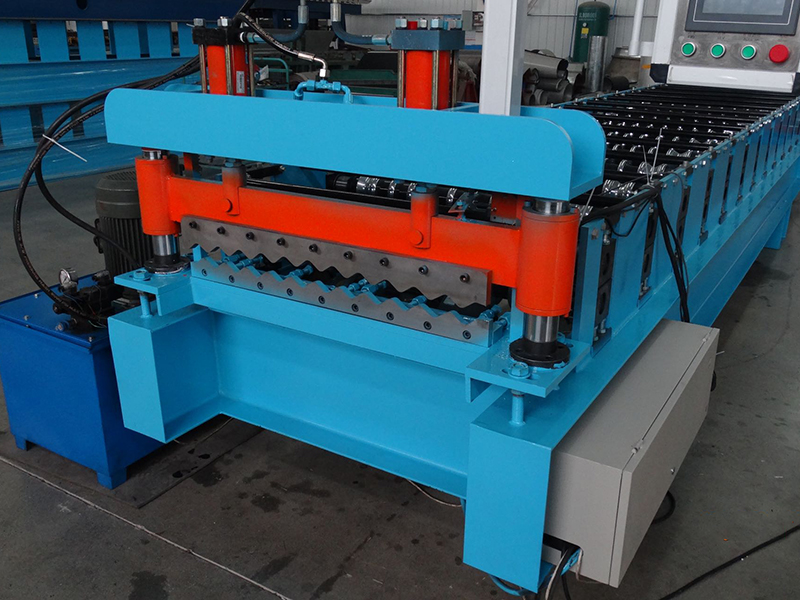

Glazed Roof Tile Roll Forming Machine

Continuously uncoiling, roll forming, pressing and cutting to make high quality tile roofing. Easy operation with touch screen.

Glazed Roof Tile Roll Forming Machine is the special roll forming machine for steel sheet cold-form industries. It can continuous form the steel sheet according to customer’s requirement, automatically uncoiling, rolling, pressing and cut to length. This equipment has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good look and so on.

The machine can be customized based on the customer's specific technical requirements.

Glazed Roof Tile Roll Forming Machine

Continuously uncoiling, roll forming, pressing and cutting to make high quality tile roofing. Easy operation with touch screen.

Glazed Roof Tile Roll Forming Machine is the special roll forming machine for steel sheet cold-form industries. It can continuous form the steel sheet according to customer’s requirement, automatically uncoiling, rolling, pressing and cut to length. This equipment has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good look and so on.

The machine can be customized based on the customer's specific technical requirements.

Highway Guardrail Roll Forming Machine

Continuously producing process. Strong structure and transmission by gear box. Cassette structure to switch profiles.

Highway Guardrail Roll Forming Machine is especially used for producing the guard rails of the road. It can continuously uncoiling, feeding, punching, roll forming, logo punching and cutting to length. The whole line adopts PLC controlling system and AV inverter speed adjustment, it can run full automatically. It is the essential equipment in the steel structure industry and road transportation industry. It adopts two cassettes to produce two profiles, i.e. two waves guardrail profile and three waves guardrail profile.

The machine can be customized based on the customer's specific technical requirements.

Highway Guardrail Roll Forming Machine

Continuously producing process. Strong structure and transmission by gear box. Cassette structure to switch profiles.

Highway Guardrail Roll Forming Machine is especially used for producing the guard rails of the road. It can continuously uncoiling, feeding, punching, roll forming, logo punching and cutting to length. The whole line adopts PLC controlling system and AV inverter speed adjustment, it can run full automatically. It is the essential equipment in the steel structure industry and road transportation industry. It adopts two cassettes to produce two profiles, i.e. two waves guardrail profile and three waves guardrail profile.

The machine can be customized based on the customer's specific technical requirements.

Automatic Ridge Cap Roll Forming Machine

Automatic working process. Accurate punching and cutting system. Easy operation with PLC and touch screen. Customized.

Ridge Cap Roll Forming Machine is especially used for producing the ridge cap, which is used for the roofing system of house and It is a kind of very welcomed modern building material. It can continuously uncoiling, feeding, roll forming, and cutting to length. The whole line adopts PLC controlling system. It can run full automatically.

The machine can be customized based on the customer's specific technical requirements.

Automatic Ridge Cap Roll Forming Machine

Automatic working process. Accurate punching and cutting system. Easy operation with PLC and touch screen. Customized.

Ridge Cap Roll Forming Machine is especially used for producing the ridge cap, which is used for the roofing system of house and It is a kind of very welcomed modern building material. It can continuously uncoiling, feeding, roll forming, and cutting to length. The whole line adopts PLC controlling system. It can run full automatically.

The machine can be customized based on the customer's specific technical requirements.

Contact Us Now