Cassette Type Sigma Purlin Roll Forming Machine

Description

Cassette Type Sigma Purlin Roll Forming Machine is especially used for producing the Sigma profile, which can be column or beam with different combination. The whole line adopts PLC controlling system and AV inverter speed adjustment, it can run full automatically.

We design the whole line separated to be decoiling, leveling, loop, servo feeding&punching, loop, roll forming unit, output. The layout arrangement is more advanced than the traditional type. Because there are loops in the line to synchronize the speed for each individual part. It adopts two cassettes to produce two profiles, i.e. Sigma profile and Z profile.

The machine can be customized based on the customer’s specific technical requirements.

Cassette Type Sigma Purlin Roll Forming Machine can do the profile according to customer’s different requirements. One machine can do several profiles, by changing the roll forming cassettes.

Work flow

Decoiling → Leveling → Pre-cutting → Lubricating → Punching → Guiding → Roll forming → Straightening → Cut to length → Output the finished products

Advanced Layout Arrangement

We design thewhole line separated to be decoiling, leveling, loop, servo feeding&punching, roll forming unit, output. The layout arrangement is more advanced than the traditional type. Because there are loops in the line to synchronize the speed for each individual part. Thus, we can achieve higher running speed.

Stable Machine Working with Gear Box Transmission

It supplies the power to the total roll forming system, it consists of reduced motor, 90 degree transfer box.

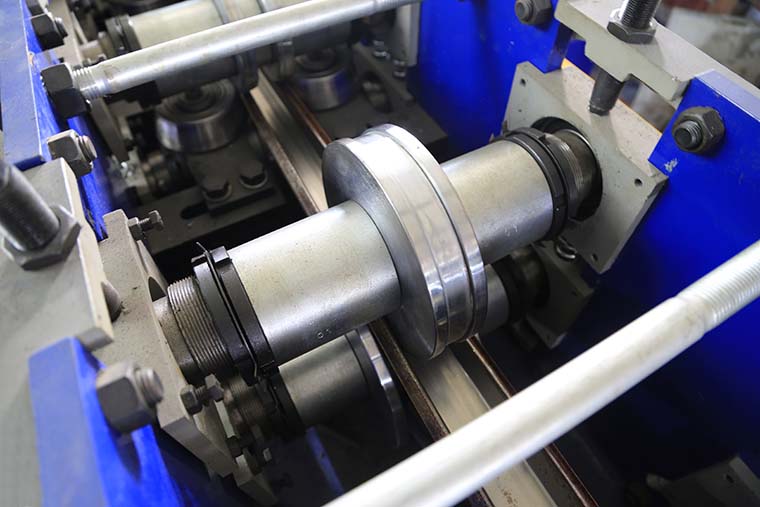

High Precision Roll Forming Unit

1. The roll former consists of frame base and forming frame.

2. The frame base adopts welding structure with good rigidity.

3. The roller adopts Cr12Mo1V1 material,

with quenching treatment. HRC58-62.

Automatic Change System

Automatic Sigma Purlin Roll Forming Machine can change Sigma profile or Z profile to be different sizes automatically. Just push the button and the rollers will automatically adjust the required sizes without being adjusted manually.

The change data will be displayed on the screen.

Fast Switch the Roll Forming Unit with Cassette

Cassette Type Sigma Purlin Roll Forming Machine can switch Sigma profile and Z profile with cassettes. It realize that one machine produce two different profiles. They are sharing one machine base and one electric system. It’s not only for saving the working space, but also saving the machine investment.Product application of Cassette Type Sigma Purlin Roll Forming Machine

In order to satisfy various customer requirements, we design and manufacture Cassette Type Sigma Roll Forming Machine in different specifications, models and configurations.

Packaging Details

1. Three *40GP containers for loading one set of the machine.

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3.Spare parts and some small parts packed in wooden box;

4.All Components Fixed by steel wire with Container. Suitable for long time sea shipping.