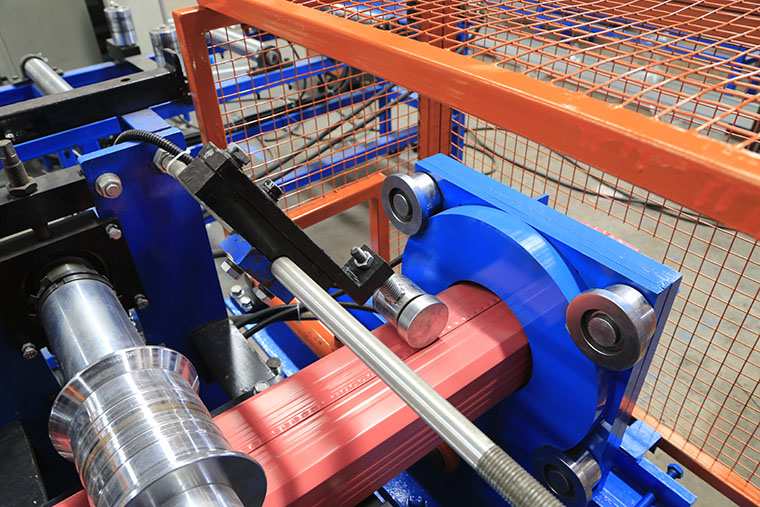

Customized Downspout Roll Forming Machine

Description

The machine can be customized as different customer is asking for different profile dimensions.

Customized Downspout Roll Forming Machine can do the profile according to customer’s different requirements.

1)Machine frame: welding structure with blasting treatment

2)The roller is made by high quality no.45 steel with hard chrome-painted

3) Roller inner supporting structure type: guiding column

4) Planetary gear speed reducer motor driven, back/forward roller driven by chain, part of upper/lower rollers driven by gear.

High Quality Cutting System

1) The cutting blade material is Cr12 with quenched treatment, there is no material wasted.

2) It adopts hydraulic cutting

Decoiling → Roll forming → Cutting → Running out

Layout drawing of Customized Downspout Roll Forming Machine

Product application of Customized Downspout Roll Forming Machine

The Downspout profile is not fixed. Most of time, we are especially manufacturing the machines according to different customers’ technical requirements.

Packaging Details

1. One *40GP container for loading one set of the machine.

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film.

3. Spare parts and some small parts packed in wooden box.

4. All Components Fixed by steel wire with Container. Suitable for long time sea shipping.