Horizontal H Beam Welding Machine

Description

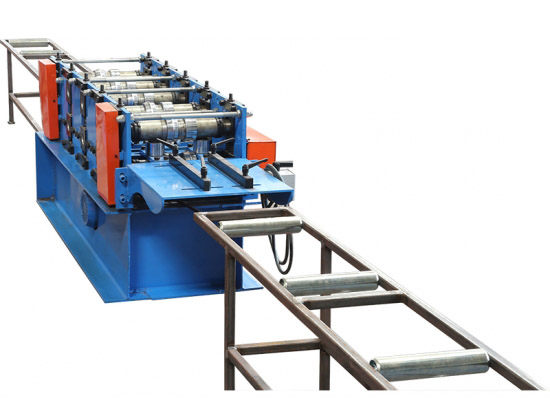

Horizontal H Beam Welding Machine for H-profile steel is a wonderful technical product that integrates mechanical, electric, and pneumatic technologies. The machine is using advanced technology of single-arc double-wire welding, greatly increases the product efficiency. It consists of welding machine, position fixing machine and conveyer.

After fixing the position for the

web and two flanges of H-profile steel, the welding machine can automatically localize,

clamp, adjust, weld, transport until finishing the all work. The automatic mode

of this line greatly lowers the cost of manufacture. JH

Compared with the traditional welding machine, Horizontal H Beam Welding Machine adopts ‘Put Through’ way to weld the H beam, so the welding speed and working efficiency is much better.

Assemble three plates to be H beam→ One surface weld (with front welder) → 180 degree turn over the H beam → Another surface weld (with back welder) → Output

H Beam Technical Parameter (Machine Working Capacity)

Horizontal H Beam Welding Machine Technical Parameter

The product of H beam can be the frame of the steel buidling, can be the crane beam, can be the column of the building...